A Guide To CNC Tube Bending Machines

Do you find out about CNC tube bending machines? These are designed in a fashion to attenuate the time of set up and to maximise manufacturing. The CNC tube bending machines can be found with many corporations. Some of the businesses have additionally launched CNC tube bending machines that characteristic electrical servo-drives on all axes and these can be found in single as well as multi stack versions.

Do you find out about CNC tube bending machines? These are designed in a fashion to attenuate the time of set up and to maximise manufacturing. The CNC tube bending machines can be found with many corporations. Some of the businesses have additionally launched CNC tube bending machines that characteristic electrical servo-drives on all axes and these can be found in single as well as multi stack versions.

CNC tube bending machines with multistack benders facilitate difficult bending without the requirement of tool change. In case, you can not apply a multistack device for stability reasons, attempt to modify over to an automated clamp die changing system that will easily accommodate up to eight clamp dies.

The CNC tube bending machines function glorious bending procedures that are programmable and boosting through the transport carriage along side the boosting in the area of stress die. The boosting tends to attenuate wall thinning towards the outer bend that further facilitates slender bending. You can easily obtain a radius of less than 1 x OD. Different necessary options of CNC tube bending machines embody the following:

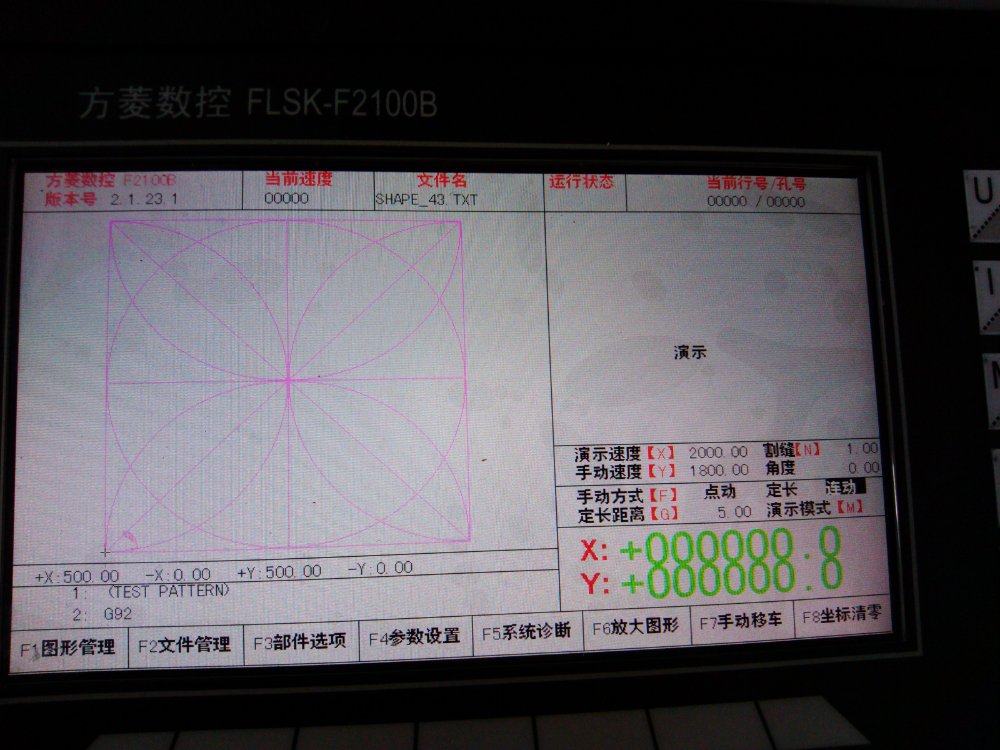

- An MMI multicontrol 2020 system

- TFT monitor

- Touchscreen

- Plausibility verification

- XYZ coordinate recalculation into bending parameters

- Versatile programming

- Multitasking

- 3-D displays

- Integrated modem

- Access to the world broad web

The integrated modem and entry to the internet works in direction of offering the better of remote upkeep and know-how help.

The CNC tube bending machines has a bending template. This helps in bending the pipe as desired. The unbent portion of the pipe is supported on a pipe that supports rail carries. It is also adjustable in height. The adjustment of peak may be simply done by a drive and it is best fitted to step-much less positioning. This simply sets the pipe-supporting rail to a top that is already specified by the CNC management unit. Earlier than bending the pipe, the peak to which the pipe has been moved, is determines through a functioning program that is dependent on a full set comprising of device knowledge that has been input into the control unit.

Listed here are the options specs of a CNC tube bending machines:

- Industrial Computer control

- I/O card machine control

- Enter of all program to industrial Laptop via contact display

- Input information of Y.B.C.

- Enter knowledge in line with Descartes X.Y.Z coordination to build bending parameter.

- The profile of tube will display on the Laptop as per the built parameter or light pole making machine input information.

- Servo-motor control that feeds axis-X as well as rotates Axis-B, and then bends Axis-C that's derived via hydraulic pressure

- Program transmits by way of flash disc, floppy disc or the World Huge Internet.

- Undertake windows XP Embed operation system.

How To buy A Press Brake

When in search of a press brake, or brake press, it's good to know what kind of press you are looking for. Press brakes are available all sizes and with many alternative choices. You should purchase a brake press that's hydraulic, mechanical, air clutch, air journey, and naturally CNC or laptop numerical managed.

When in search of a press brake, or brake press, it's good to know what kind of press you are looking for. Press brakes are available all sizes and with many alternative choices. You should purchase a brake press that's hydraulic, mechanical, air clutch, air journey, and naturally CNC or laptop numerical managed.

It's good to first know your Capability, which is rated by tonnage. Then you want to know the legnth and distance between housings. The distance between housings is normally smaller than the capability of the machine. When you are looking to bend 10' and need to go previous the gap, you will have a 12' brake.

It's good to first know your Capability, which is rated by tonnage. Then you want to know the legnth and distance between housings. The distance between housings is normally smaller than the capability of the machine. When you are looking to bend 10' and need to go previous the gap, you will have a 12' brake.

As for the clutch, Hydraulic clutch is the safest, and most expensive. They are generally slower and have extra of a precise bend.

Air clutch machine work in the identical manner except they use air to activeat the clutch. The distinction is that you've got to complete the rotation once activated. This makes it extra dangerous, but faster.

Air Journey, is a less expensive, sometimes aftermarket clutch system that can be added to an ordinary mechanical brake press.

Mechanical is the most dangerous of them all, you lose a number of management. The clutch has to make a full rotation, and cannot be stopped at any time during the process.

CNC press brakes are the newest in manufacturing. They'll have mutiple axis Backgauges, and you may program them to do totally different bends. This is essentially the most expensive and the best for manufacturing.

Discover exactly how to operate the press brake equipment

To get essentially the most of a device or piece of tools, you really have to know the way it works. That is true in all strains of work, and for a press brake operator it isn't any different. Press brakes are great property to any metal workshop, however only if operated accurately. If they are not, pole welding machine they might end up as costly pieces of junk. I due to this fact current to you a number of pointers on the right use of press brakes.

Nice drawings = nice outcomes

To ensure that the press brake operator to produce high quality elements, she must first have a high quality drawing in her arms. A great technical drawing ought to contain all doable details regarding the part to be manufactured, and the drawing ought to be made with a selected brake and its tooling in thoughts, to guarantee that the part can really be made on a selected machine. Many specifications of a press brake matter to the work process, and should not be ignored when producing the drawing. For an instance, it would not make sense to specify that an element be bent off-heart, if this have been to exceed the specs and cause harm to the machine. Drawings should after all include all crucial measurements, dimensions and tolerances. They should be made by someone who understands the brake, and the way a typical work course of on it'd unfold.

The operator and her press brake

No matter the level of automation a chunk of equipment has reached, there'll always be a human behind - an operator. That particular person must have intimate data of the machine; its capabilities and its limits in equal measure. Even bleeding edge press brakes, cnc-controlled and fed by robots - will be worthless if the operator lacks the information to wield the expertise. The operator should know, when she sees a drawing for a brand new part, whether or not the work can be carried out on her machine. She must know what tooling to use, and in what order. Know whether or not to use air bending, bottom bending or coining strategies to achieve the purpose. Information is important every step of the way in which, which makes enough training essential too.

Skimp on the educational, and the quality and productiveness will undergo. Figuring out the max tons-per-inch limit for example, could imply the difference between using a press brake to its fullest potential - or exceeding that potential and wrecking the machine by upsetting the ram.

Tooling is one other essential subject, and it's up to the operator to decide on the fitting punch and die for the job.

No single mixture will do all the things, so expertise and imagination is required to choose what works greatest in a given situation. And do remember to examine if the tooling is up to its manufacturing unit specs - until you want your work to be below par, in fact.

Guide To Plasma Cutters

Plasma cutters can cut steel and different metals of various thicknesses using a plasma torch. Plasma can also be used for plasma arc welding and pole welding machine other functi

Plasma cutters can cut steel and different metals of various thicknesses using a plasma torch. Plasma can also be used for plasma arc welding and pole welding machine other functi

s.

In the event you loved this information and you want to receive more info with regards to pole welding machine - https://poleequipment.com, assure visit our web-page.